As a producer of the finest cannabis, you are constantly striving for the best quality cannabis, grown and processed at the lowest cost with an easy-to-manage process. Without a doubt, a smooth continuity of your process is high on your priority list. Deploying a quality cannabis drying system helps you to achieve this.

Different drying methods

In the life cycle of every agricultural product, innovation plays a vital role. Though cannabis is grown and processed for some millennia, the real growth of the cannabis market only started substantially in the 2nd half of the 2nd decade of this millennium. The market grew but some techniques did not grow along with the market.

Some cannabis farms still use the hang drying method with (minor) product improvements. Some farms have switched to the ‘new’ rack drying method, applying some (minor) improvements. But the drying process is still not professionalized enough. In this news item, we discuss a new and advanced method of drying cannabis for professional growing farms: Top-Down drying.

Cannabis-Drying.com

The company behind this Top-Down drying method is Cannabis-Drying.com. Cannabis-Drying.com is a subsidiary of a Dutch-based, privately owned company, founded in 1974. From day one, the company

played a substantial, innovative role in the niche market of drying and storing agricultural products. They have developed and implemented new, groundbreaking techniques for the drying and storing of flower bulbs, seed, garlic and other agricultural products. Doing this, thousands of farmers saved money and time considerably.

The systems of Cannabis-Drying.com’s holding company are used in over 50 countries on all six continents. Clients are both multibillion-dollar, stock listed companies (USA & Europe) and small local farms as well. Cannabis-Drying.com is staffed by a team of draughtsman and engineers, with each expert having an average experience of over 10 years.

Strenghts of the Top-Down drying method

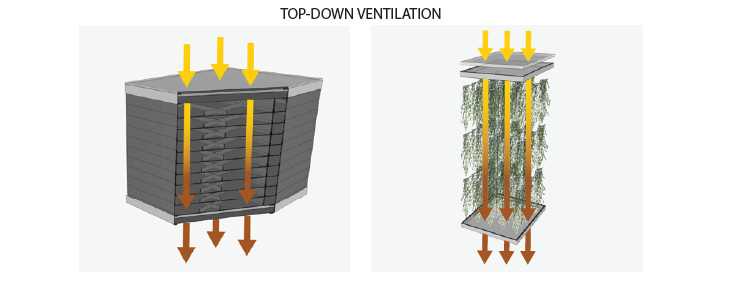

- Air flowing through and along each single bud, resulting in an evenly dried, superior end-product

- Most efficient logistics and use of m2 / ft2

- Saving on labor costs

- Clean air through nano-filtering (HEPA & Pad), reducing mold, mildew, pests and bacteria to practically zero.

- Remote & fully controlled cannabis drying management

- Right after harvest until packaging, all cannabis can stay in trays and a cleanroom environment.

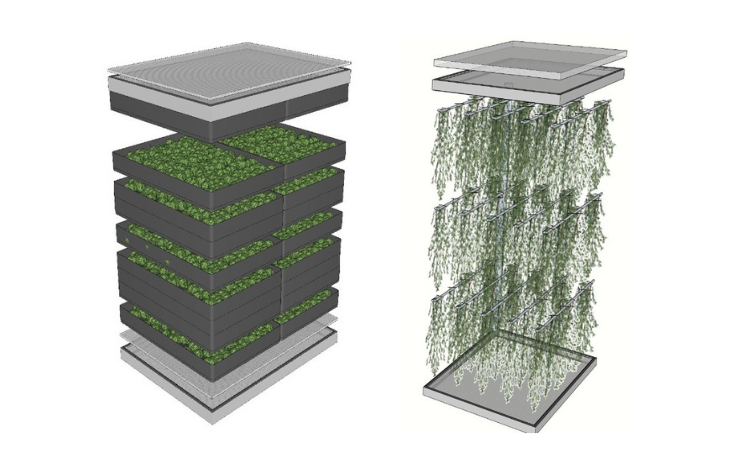

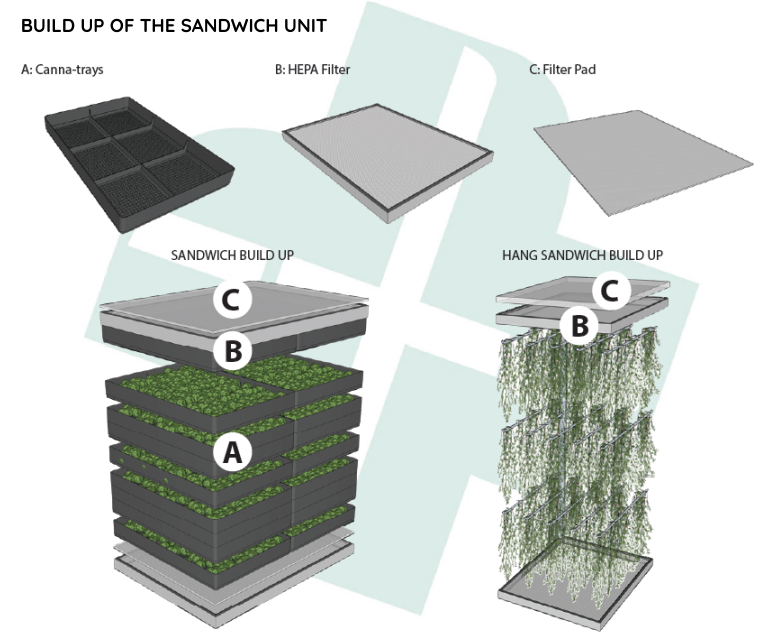

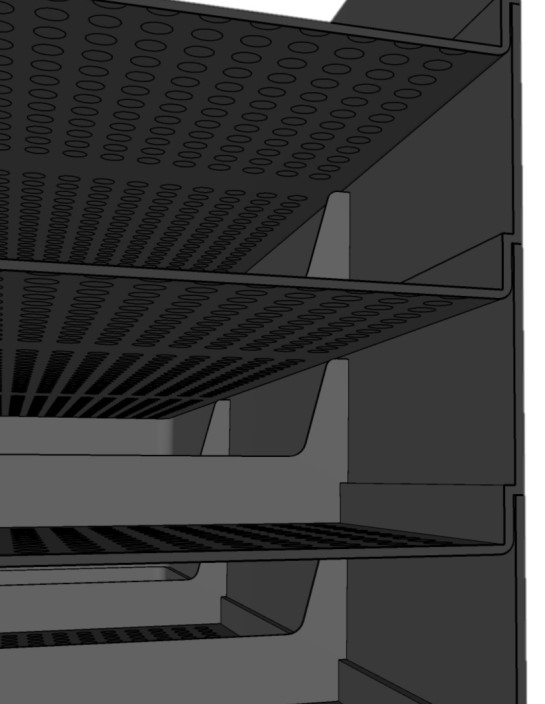

Sandwich units

With the SANDWICH TOP-DOWN DRYING METHOD, every part of the cannabis gets a constant controlled, top-down flow of process air. Systems are available for tray drying and hang drying. So, wet and dry trimming is both possible with these systems.

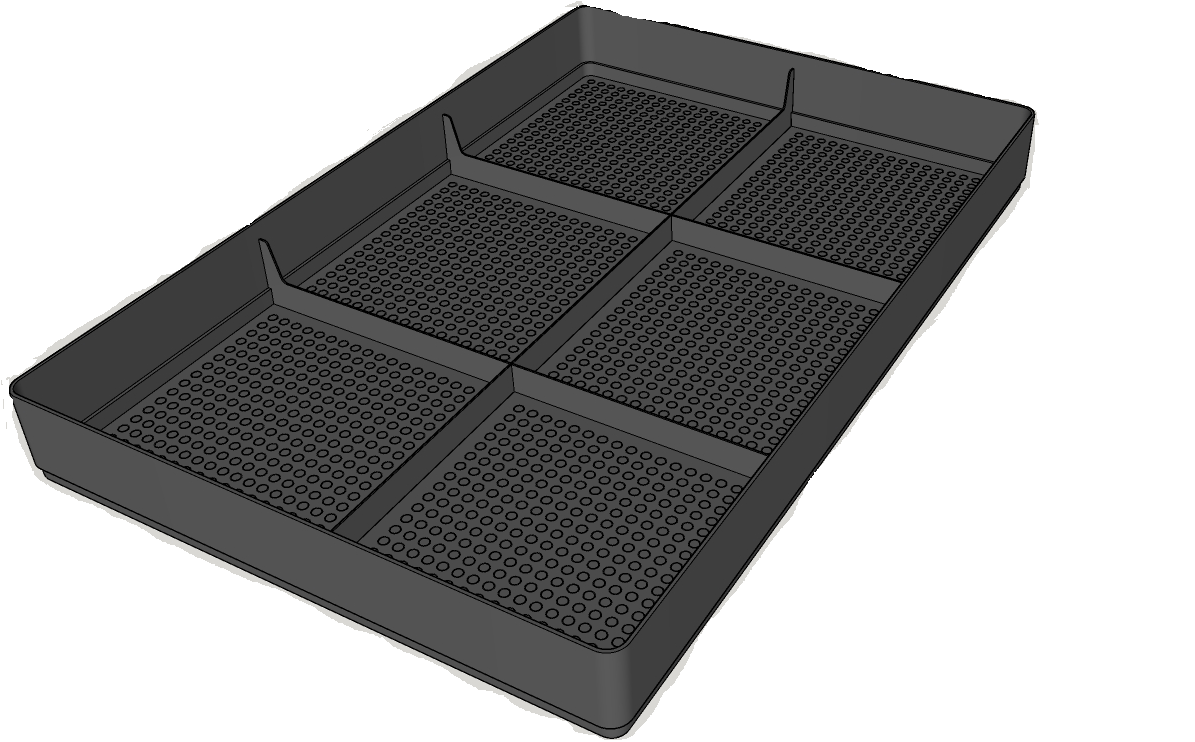

A: Canna-Tray

A Canna-Tray is where the cannabis is placed after harvest. Each Canna-Tray is divided into six low compartments preventing the cannabis from moving around and to make sure all the cannabis is evenly dried.

A Canna-Tray is made of an anti-static ABS thermoplastic compound. Anti-static prevents the trichomes from sticking to the Canna-Tray.

Each Canna-Tray has 1944 round holes of 6 mm (0.24-inch diameter) in the bottom of the Canna-Tray. The holes ensure a continuous and equal top-down flow of controlled and cleaned process air throughout the duration of the drying (& curing) process.

Properties of the Canna-Tray:

- Anti-static ABS (acrylonitrile-butadiene-styrene) thermoplastic (same as LEGO)

- Resistant against chemicals like thinned acid, alkaline, oils, fat and aliphatic hydrocarbons

- Food Safe

- Very strong

How is the Canna-Tray used?

.

- Easily stackable with exact precision and simplicity

- Easy cleanable

- 100% recyclable

- Size 600x400x60 mm (23.5 x 15.5 x 2.4”)

- Maximum service temperature 77°C (171°F)

A Canna-Tray is filled with wet or dry trimmed cannabis.

The Canna-Tray is placed on a HEPA filter and is the middle layer of the Sandwich-unit.

A maximum of 21 layers of Canna-Trays can be placed in the Sandwich-unit.

Cleaning the Canna-Trays

To make sure the Canna-Trays are properly cleaned after each drying cycle, we offer the Canna-Tray washer. The Canna-Tray washer works with an alkaline cleaner and is capable of cleaning 220 Canna-Trays each hour. Canna-Tray washers with a higher capacity are available.

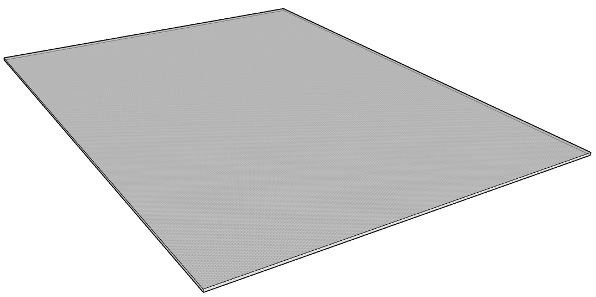

B: HEPA filter

To get the best clean air conditions — eliminating all risks: viruses, pests etc. — Cannabis-Drying.com’s Top-Down drying method uses two types of filters: a HEPA (nano) filter and a filter pad.

The High Efficiency Particulate Air (HEPA) filter is made of micro-glass fiber sheet, meeting the highest European and U.S. standards. HEPA filters are used for specific clean rooms in hospitals, pharmaceutical, nuclear and micro-electronics industry. So they are suitable for medical and recreational cannabis.

It filters out:

• Bacteria

• Pollen

• Nanoparticles

• Mold

• Exhaust gases

• Dust

• Pests

• Hair

• Mildew

Filters all air before it reaches the cannabis and when the air leaves the cannabis. This ensures the cannabis remains in a clean room environment.

How the HEPA Filter is used?

- As the bottom layer of a Sandwich-unit.

- Perfectly designed to stack 2 piles of Canna-Trays on it.

- As the top layer of a Sandwich-unit.

Properties of HEPA filters:

- Consistent high performance.

- Large filter surface.

- Robust extruded aluminum frame.

- Low energy consumption, thanks to smart pleating methods.

- Proven quality, in cleanroom environments in hospitals, the pharmaceutical industry and the micro-electronics industry.

.

- Filtering category ePM1 according to ISO 16890 (the world standard).

- Filters particulate matter of 0,3 ≤ × ≤1 micron.

- 1 micron = 1μ= 0.001mm.

- Filtering category H13, filtering ePM1 99.95%.

- Size of the frame: 600x800x45 mm (23.5 x 31 x 1.8”).

C: Filter pad

Each Sandwich-unit has 2 layers of filter pads. Both are right above each HEPA filter layer (bottom & on top)

How the Filter Pad is used?

At the bottom, any plant material that fall off the cannabis during the drying (& curing) process are collected. On the top of the Sandwich-unit, it protects the HEPA filters against dust.

Cannabis drying Solutions

Cannabis-Drying.com has a drying solution for low and high quantities. Below you will find an overview of the different options. If you would like to have detailed information about all of these options, please click here to visit Cannabis-Drying.com’s company profile page here on Cantopia, or click on the links below the illustrations.

GMP

To make sure the drying cabinet, drying racks and hang drying racks can be used for medical cannabis production, these products are in the process of full GMP cerfication for this product. The drying cabinets, drying racks and hang drying racks will soon be available with all the GMP-protocols for operating and cleaning the machine. Cannabis-Drying.com can even implement these GMP-protocols in your existing GMP-system.

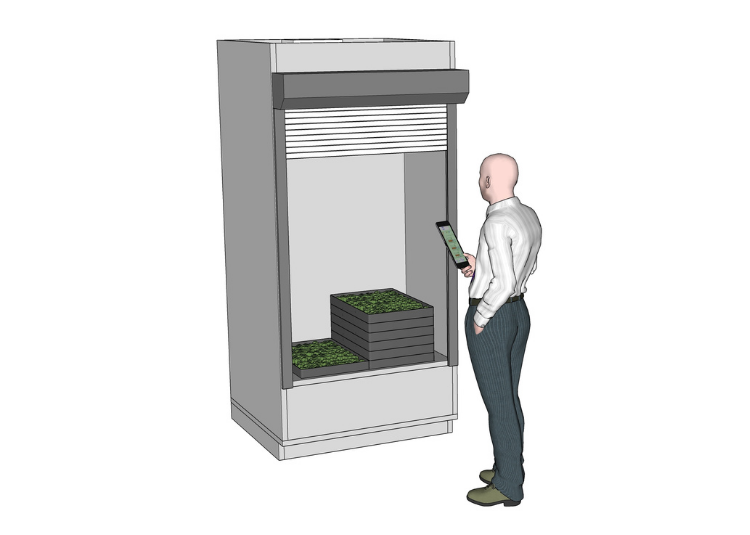

Drying automatically

To arrange drying automatically; the temperature, humidity levels and amount of airflow are being controlled. Therefore, Cannabis-Drying.com developed the ABC-processor. The ABC-processor allows you to dry as fast or slow as desired, drying in 3-15 days is possible. The ABC-processor is operated by a touch panel on the installation or by a mobile device. Each of Cannabis-Drying.com’s installations has a different version of the ABC-software.

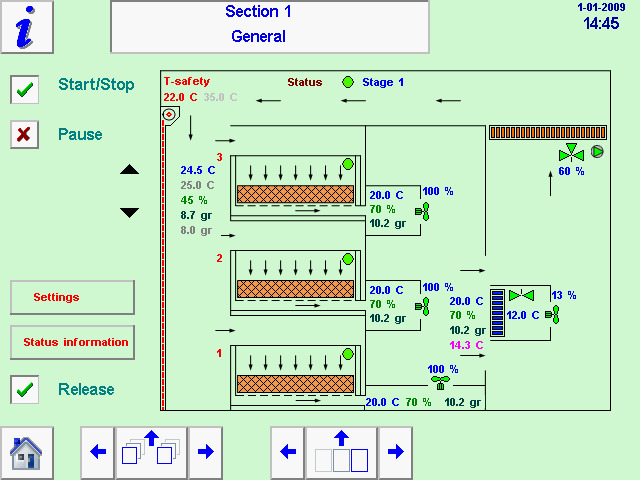

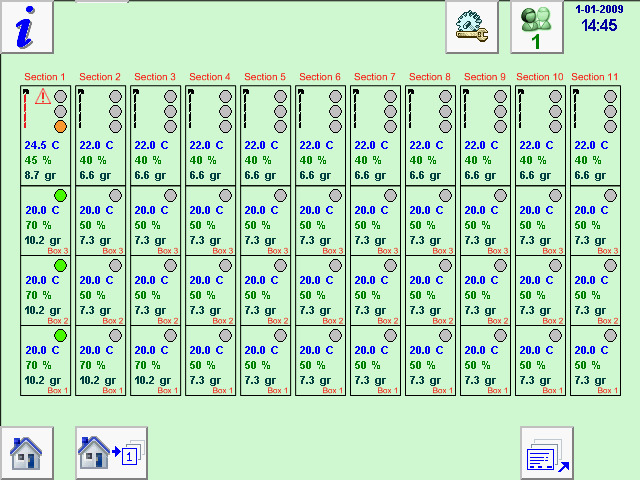

Managing the ABC-HVAC controller

For Cannabis-Drying.com proudly presents the ‘ABC’ HVAC -system. The HVAC controller is made and maintained in-house. It holds over 35 years of stable and proven innovations. The system consists of a processor and a software program. It is implemented in thousands of control systems – in various agricultural sectors worldwide – in all 6 continents – over 50 countries. With this world-renowned technology, Cannabis-Drying.com guarantees that you can set optimal drying conditions for your own cannabis business process and gain substantial benefits. The ABC-processor allows you to dry as fast or slow as desired, drying in 3-15 days is possible.

How is the ABC -HVAC Controller used?

Our ABC processor and software enable easy management of the drying and curing process every step of the way. You can set it the way you want. You can easily manage the process on a touch panel just outside the rooms or manage on a remote device (tablet, laptop, mobile phone) on a holiday resort.

- Adjust the temperature, absolute/relative humidity and airflow.

- Flexibility: You can create presets for various processes and special strains.

- Inhouse technical engineering department can produce tailormade processes, if needed.

- MCM module: control the ABC-processor from a tablet or mobile phone (optional).

- PC software: operate the ABC-processor from your PC.

- Real time and immediate support is given by our own support engineers via your pc with TeamViewer.

- SMS alert (optional).

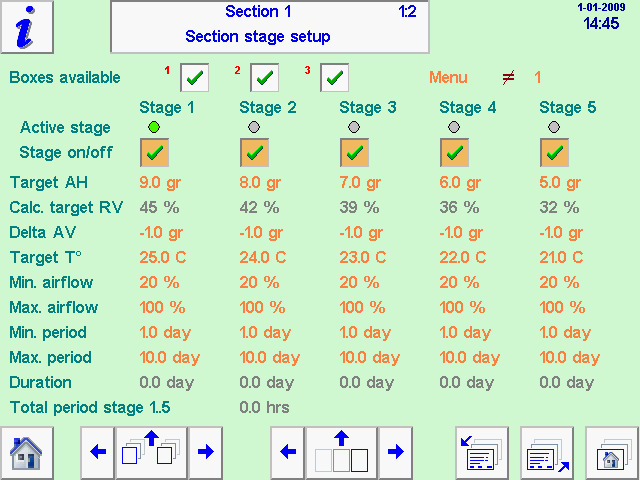

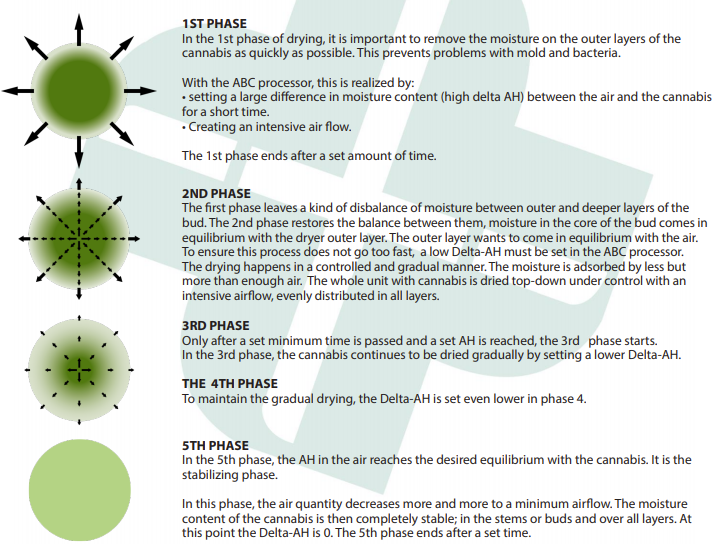

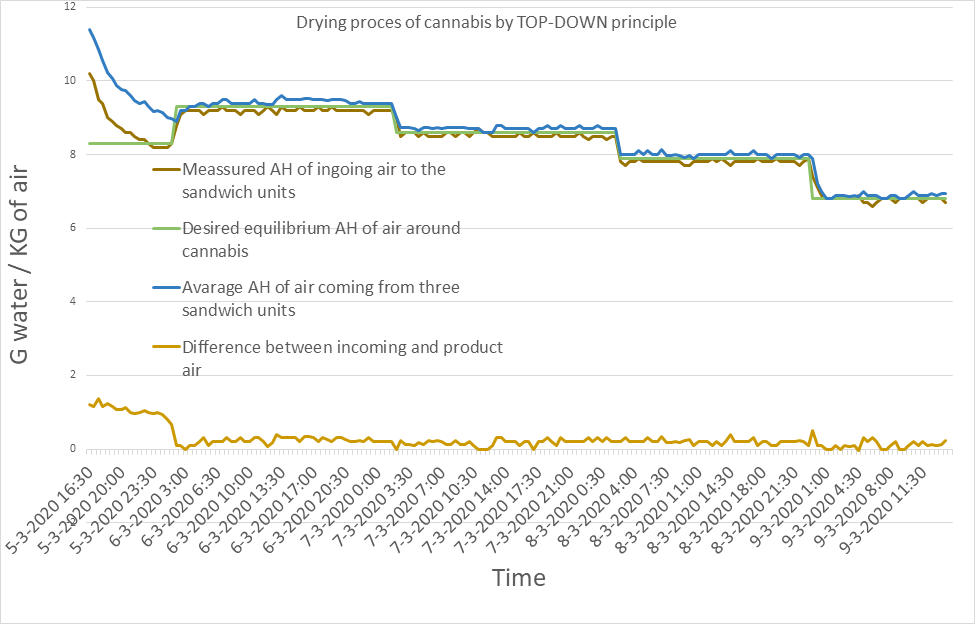

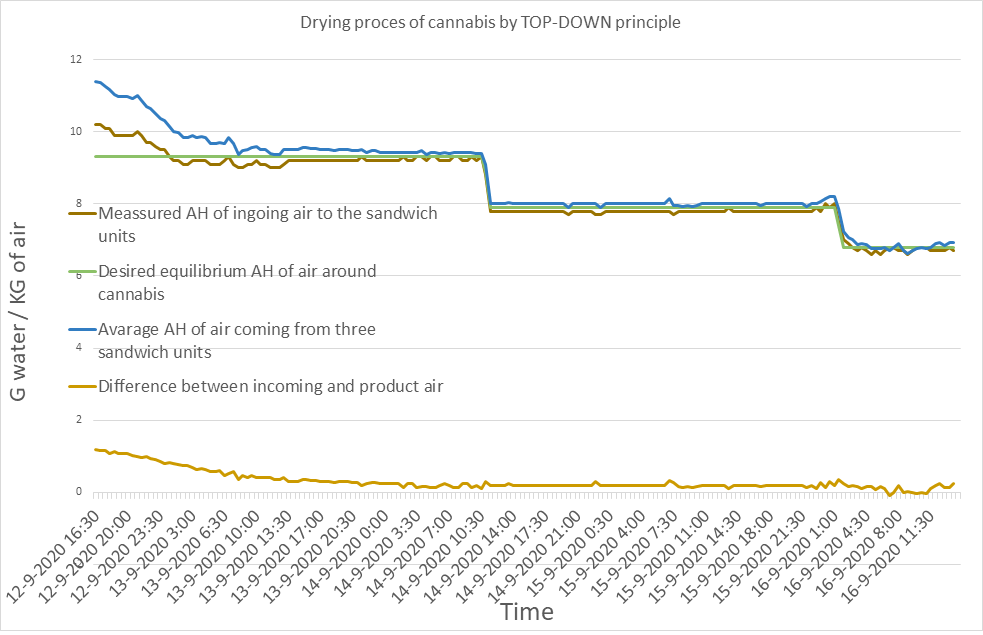

ABC-HVAC processor and the phases of drying

In nature, everything wants to gain balance. When the humidity of an agricultural product like cannabis is high and the humidity of the airflow passing through it is low, the cannabis will release its moisture to the air. Thus, creating an equilibrium of moisture. When an equilibrium has been reached, moisture exchange is stopped. At this point, the cannabis will not dry any further, no matter how much airflow (of that same quality) passes through the cannabis. So, with the correct temperature and RH (and therefore, the correct Absolute Moisture, AH), the cannabis will never become too dry. Consider that the drying of cannabis should not take place too fast.The ABC-processor allows you to set 5 phases of drying. In each phase, a different AH, airflow and temperature can be set. The next phase will only start after a set time and after reaching a set AH. The ABC drying we call ‘Optimal’, meaning it occurs gradually and at a certain speed.

Conclusion

- Due to the intensive airflow, the product dries evenly over all layers of the drying installation.

- Because a desired lower moisture content is set in each phase, the cannabis is gradually dried.

- A minimum drying time is set at each stage so that the cannabis has enough time to transform from CBGA to THCA, CBDA and CBCA.

- With the correct moisture content of the air per phase, the product never becomes too dry and dries evenly over all drying layers.

.

- With an optimal drying process, mold and bacteria are reduced to a minimum.

- The ABC processor enables this controlled drying in 5 stages:

1st phase: removes sufficient moisture to prevent the development of mold and bacteria.

2nd to 4th phase: gradually drying the product to a lower moisture content per phase

5th phase: achieving the desired moisture content of the cannabis. - Each phase employs a set time, so that drying takes place in the desired time.

Examples of the cannabis drying process:

Drying methods compared

More information

For detailed product information about all of these options, please click here to visit Cannabis-Drying.com’s company profile page here on Cantopia.

If you are interested in the drying solutions that Cannabis-Drying.com has to offer, you can get in direct contact using the contact information below.